HelloI'm a new member and have a question

15 posts

• Page 1 of 2 • 1, 2

HelloI'm a new member and have a question

Hi everyone.I'm new to this forum and hope I can contribute to it in the future.Right now I have a question.I bought a Marbelite MY-6 signal controller which I should receive later this week.I bought it with hopes of restoring it if need be to control my old Marbelite signal.I haven't seen much on the internet or ebay as far as info or parts for this thing.Can anyone point me in the right direction?Or am I screwed if this thing needs parts to get it working?Thanks,Chris.

- Blackhawks1

Re: HelloI'm a new member and have a question

Open a photobucket or other image hosting sight account to post pictures in "Signal Controllers", So we (All the forum memebers) can see the pictures of what you may need and/or have.

Well what do you know. If I put my name here, I do not have to sign it everytime.

Phil

Used Traffic Signal Equipment Expeditor

http://www.twingreenonline.com/

https://www.facebook.com/Twin.Green.Traffic.Signal

https://www.facebook.com/Traffic.Light.King

Phil

Used Traffic Signal Equipment Expeditor

http://www.twingreenonline.com/

https://www.facebook.com/Twin.Green.Traffic.Signal

https://www.facebook.com/Traffic.Light.King

-

2070 - Crusty Old Salt

- Posts: 9975

- Joined: Tue Sep 02, 2008 8:29 pm

- Location: Columbia County, New York

Re: HelloI'm a new member and have a question

Welcome Chris. You're in luck on the controller. The eBay seller contacted me with a second offer (he had two) so I have one on the way also. Parts are hard to come by. Hopefully like most of them, all they need is some cleaning and TLC.

I be running a thread on what I end up doing with mine. We can compare notes.

I be running a thread on what I end up doing with mine. We can compare notes.

Joe N

-

TacomaJoe - Crusty Old Salt

- Posts: 2550

- Joined: Mon Oct 12, 2009 8:48 pm

- Location: Tacoma, WA

Re: HelloI'm a new member and have a question

Thanks!Phil,I'll have my girlfriend help me with photobucket.She's a lot better with that stuff than I am.I actually have two signals.One's aluminum.I'd say '60s vintage Marbelite.The other one's newer '90s model w/12" lenses.TacomaJoe:I'll let you know when I receive the controller.Hopefully both of ours don't need too much work,although that's half the fun for me.As long as parts availability doesn't become too much of an issue.I thought about buying one of those electronic controllers,but I like the nostalgia of having a "real"controller doing the work.Just might be a little louder!Thanks again.

- Blackhawks1

Re: HelloI'm a new member and have a question

Hey, Chris. Welcome to the forums. Show us what your MY-6 looks like. It looks like a neat, little signal controller, since some other members (aside from TacomaJoe) own it, too.

Unfortunately, Marbelite in New Jersey wouldn't have the parts that you would need for the controller. In their book, that signal controller is history (along with their other electro-mechanical signal controller models as well). They have only a handful of spare parts for their electro-mechanical signal controllers, like cycle gears, contacts, and cam fingers.

Good luck with it. I'm sure some people here could provide you with other necessary parts for it to work as it once did.

Unfortunately, Marbelite in New Jersey wouldn't have the parts that you would need for the controller. In their book, that signal controller is history (along with their other electro-mechanical signal controller models as well). They have only a handful of spare parts for their electro-mechanical signal controllers, like cycle gears, contacts, and cam fingers.

Good luck with it. I'm sure some people here could provide you with other necessary parts for it to work as it once did.

Steven G.

-

steven1981 - Crusty Old Salt

- Posts: 3552

- Joined: Tue Jun 29, 2010 1:09 pm

- Location: Manahawkin, NJ

Re: HelloI'm a new member and have a question

Hey Chris,

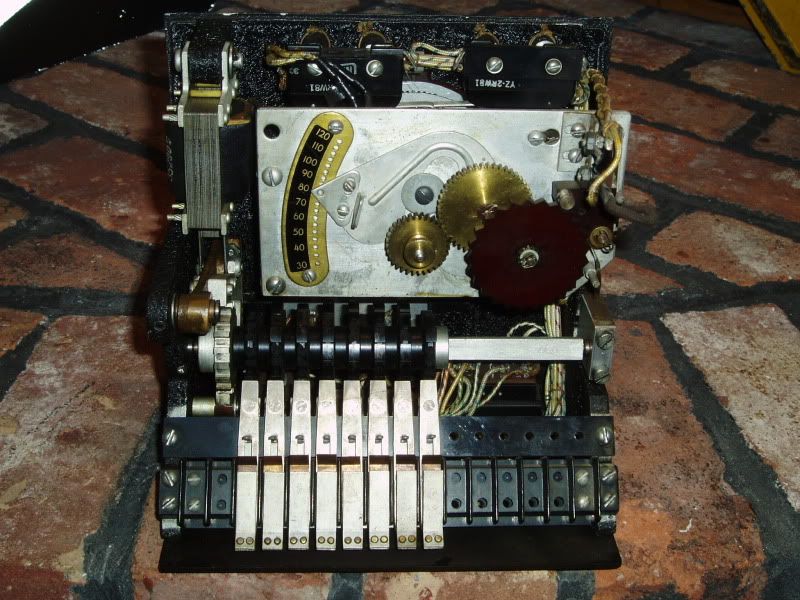

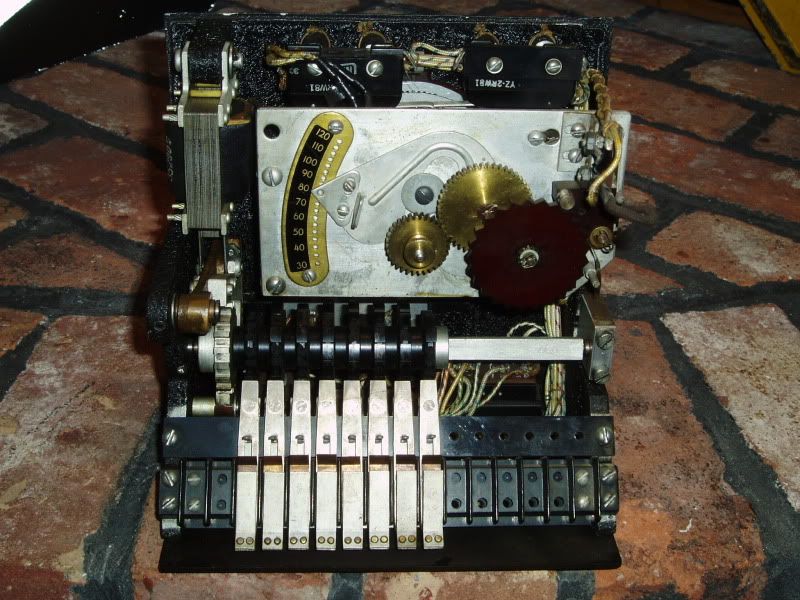

I also have one of these controllers. Like Joe said, parts are hard to come by. Without the cabinet, back panel, and schematic, I'm going to have to figure out each pin in the connector. So far I applied power to make sure the dial motor works, which it does. Here are some photos of mine. It just seems to have a different dial than yours.

I also have one of these controllers. Like Joe said, parts are hard to come by. Without the cabinet, back panel, and schematic, I'm going to have to figure out each pin in the connector. So far I applied power to make sure the dial motor works, which it does. Here are some photos of mine. It just seems to have a different dial than yours.

-

Mike80 - Crusty Old Salt

- Posts: 1342

- Joined: Thu Oct 30, 2008 6:34 pm

- Location: Suffolk County, Long Island, NY

Re: HelloI'm a new member and have a question

Thanks for the pictures,Mike.My controller finally came in today.At first I thought pieces were broken.The cam had parts that appeared broken.I think that's actually how the light duration is controlled.Looks like it's made out of bakelite.The final driven gear for the dial does not line up completely with the mating drive gear.That's one of the first things I noticed will need to be addressed.I'm not going to apply line voltage to it until I test the motor winding resistance,etc.I'm wondering what is the best way to clean up all the contacts and help protect them from excessive wear?(Besides not putting an excessive load on them.)How about the gears?Once I get this thing cleaned up and restored,I want it to last.I'm going to get my photo bucket acct. started soon and download some pics. as soon as possible.I'm working a lot of hours right now so I'm kinda limited on time to do this stuff.This is a really neat little mechanical device you just don't see anymore.Thanks for all the feedback.I'll send updates soon. :)

- Blackhawks1

Re: HelloI'm a new member and have a question

The final driven gear for the dial does not line up completely with the mating drive gear.

One of the gears determines the cycle time and is interchangeable. There is a screw to loosen, then the plate with the mating gear can move. Tip: a 50% mess will work, if they are too close together they could jam.

I'm wondering what is the best way to clean up all the contacts and help protect them from excessive wear?

If they are really crusty, knock the chunks off with a dental pick. Very light on some emery cloth is all that's needed. The fingers ride on the bakelite cams and don't wear much. The cams determine which lights are on during each interval. The dial keys determine how long each interval will be.

When you have things apart you will see where to oil. Light motor oil, don't over oil, the excess will drip out, collect dirt and gum up. These motors are low torque, slow speed.

I haven't got mine yet, should be soon. Then I'll have photos to go with the words.

One thing you will need is the 15 pin connector, eBay $14. I'll be getting a wiring diagram put together as soon as I something to look at.

Joe N

-

TacomaJoe - Crusty Old Salt

- Posts: 2550

- Joined: Mon Oct 12, 2009 8:48 pm

- Location: Tacoma, WA

Re: HelloI'm a new member and have a question

Hey,Joe.Looked on eBay for that 15 pin connector.Had no luck.What key word should I use to find this thing?Thanks.

- Blackhawks1

15 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: SignalFreak and 0 guests